India's #1 ABD Bio Septic Tank manufacturer

HBR STP

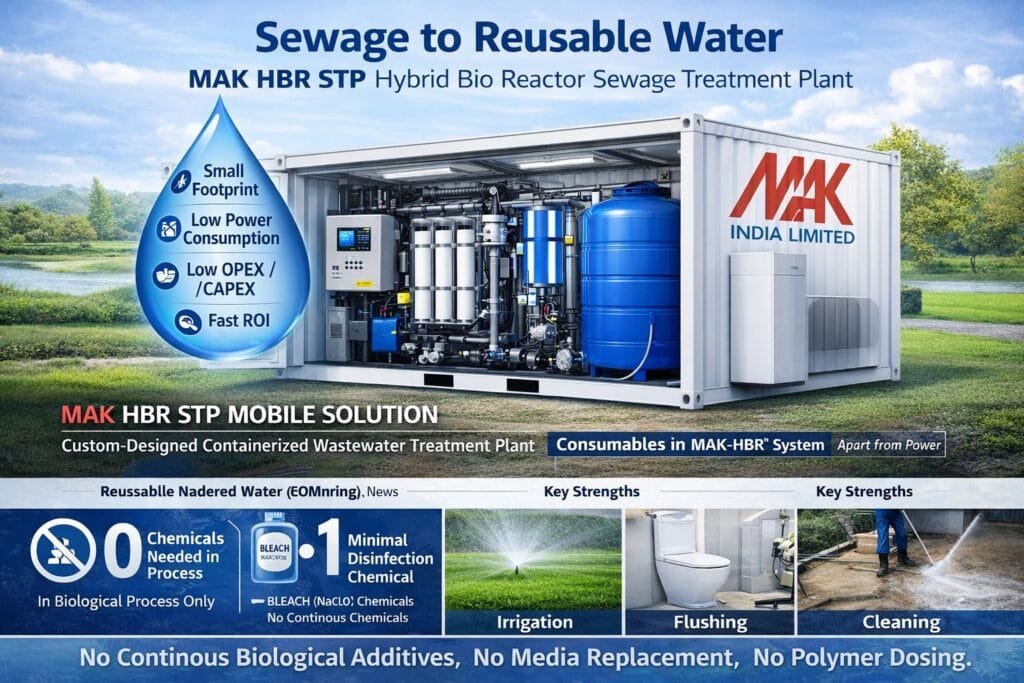

MAK HBR STP Technology

Consumables in MAK-HBR™ System (Apart from Power)

Short, Direct Answer (Board-Level)

MAK-HBR™ has very minimal consumables. There are no continuous biological chemicals, no media replacement,

and no polymer dosing. Consumables are limited mainly to disinfection chemicals and minor wear parts.

1) Biological Process – NO consumables

This is a key strength of MAK-HBR™. Once seeded, the biology sustains itself.

| Item | Requirement |

|---|---|

| Nutrients (Urea / DAP) | ❌ Not required (domestic sewage has enough) |

| Bio-culture dosing | ❌ Not required (self-sustaining biomass) |

| Enzymes | ❌ Not required |

| Coagulants / Polymers | ❌ Not required |

| Media replacement | ❌ Not required (10+ year life) |

Key point: Once seeded, the biology sustains itself.

2) Disinfection – Only regular consumable

A) Chlorine (Mandatory)

- Chemical: Sodium Hypochlorite (5–10%)

- Purpose: Primary disinfection

- Typical consumption (1 MLD):

- 2–4 kg chlorine equivalent / day

- ~₹300–₹600/day (varies with concentration & price)

✅ This is the only regular chemical used.

B) UV / IR (Backup)

- No chemical consumption

- Only:

- Power

- Lamp replacement once in 8,000–10,000 hours (≈ 12–18 months)

✔ Treated as periodic maintenance, not a consumable.

C) Ozone (Standby / Emergency only)

- No chemical storage

- Uses:

- Power

- Dry air or oxygen (ambient air usually sufficient for micro-ozone)

- Runs only when needed, so OPEX impact is negligible

✔ Considered a safety feature, not a daily consumable.

3) Filtration (PSF) – Very low consumables

| Item | Frequency |

|---|---|

| Sand / Anthracite media | Replace once in 4–6 years |

| Backwash water | Uses treated water (no cost) |

✔ No chemical cleaning required in normal operation.

4) Sludge Handling – No chemical use

- Sludge wasting is mechanical only

- No polymer dosing (because lamella clarifier + controlled MLSS)

- If needed:

- Manure route: mix with garden waste (no chemicals)

- ABD / biogas route: no chemicals

✔ This is why MAK-HBR aligns with a zero-sludge / zero-chemical philosophy.

5) Wear & Tear Items (Maintenance, NOT consumables)

These are periodic replacements, not daily consumables:

| Item | Typical Replacement |

|---|---|

| Diffuser membranes | 4–6 years |

| DO / pH probe tips | 12–24 months |

| Pump seals | 2–4 years |

| UV lamps | 12–18 months |

| Screens / belts | 3–5 years |

✔ Planned maintenance, not an OPEX burden.

6) What MAK-HBR Does NOT Need (Important Comparison)

| Item | ASP / SBR / MBR | MAK-HBR™ |

|---|---|---|

| Alum / PAC | Often required | ❌ Not required |

| Polymer | Required for sludge | ❌ Not required |

| Frequent culture dosing | Common | ❌ Not required |

| Membrane chemicals | Required | ❌ Not applicable |

7) Typical OPEX Split (Excluding Staff)

For 1 MLD MAK-HBR™:

- Power: ~70–75%

- Chlorine: ~15–20%

- Maintenance spares: ~5–10%

- Others: negligible

👉 Chemicals (other than chlorine) ≈ ZERO

“Apart from power and a small quantity of chlorine for disinfection, MAK-HBR™ does not consume chemicals.

The biological process is self-sustaining and chemical-free.”

10-Year Life-Cycle Cost Comparison

(Per 1 MLD Capacity | Typical Indian Sewage | FY 2025 prices)

Assumptions (Transparent & Conservative)

- Operation: 365 days/year

- Treated volume: 365,000 kL/year

- Power tariff: ₹7/kWh (average institutional)

- No escalation considered (to keep it conservative)

- Major replacement costs included where applicable

A) Annual OPEX Summary

| Item | MAK-HBR™ | SBR | MBR |

|---|---|---|---|

| Power (₹ Cr/year) | 0.45 | 0.55 | 1.05 |

| Chemicals (₹ Cr/year) | 0.08 | 0.10 | 0.25 |

| Maintenance & Spares (₹ Cr/year) | 0.07 | 0.10 | 0.20 |

| Manpower (₹ Cr/year) | 0.05 | 0.08 | 0.12 |

| Total OPEX / Year (₹ Cr) | 0.65 | 0.83 | 1.62 |

| OPEX per kL (₹) | ₹3.9 | ₹5.6 | ₹11.0 |

B) Major Periodic Replacement Costs (10-Year Horizon)

| Item | MAK-HBR™ | SBR | MBR |

|---|---|---|---|

| Diffusers / Wear Parts | 0.25 | 0.30 | — |

| Decanters / Valves | — | 0.30 | — |

| Membrane Replacement | ❌ Nil | ❌ Nil | 2.00 |

| Instrument Probes (DO/pH etc.) | 0.15 | 0.15 | 0.15 |

| Total Replacement Cost (₹ Cr) | 0.40 | 0.75 | 2.15 |

C) 10-Year Life-Cycle Cost (Excluding Civil CAPEX)

| Cost Head | MAK-HBR™ | SBR | MBR |

|---|---|---|---|

| 10-Year OPEX (₹ Cr) | 6.50 | 8.30 | 16.20 |

| Replacement Costs (₹ Cr) | 0.40 | 0.75 | 2.15 |

| Total 10-Year LCC (₹ Cr / MLD) | 6.90 | 9.05 | 18.35 |

D) Cost Advantage Summary

| Comparison | Savings with MAK-HBR™ |

|---|---|

| vs SBR (10 years) | ₹2.15 Cr / MLD |

| vs MBR (10 years) | ₹11.45 Cr / MLD |

| % Saving vs MBR | ≈ 62% lower |

E) 400 MLD Scale Impact (BWSSB Context)

| Technology | 10-Year LCC for 400 MLD (₹ Cr) |

|---|---|

| MAK-HBR™ | ≈ 2,760 |

| SBR | ≈ 3,620 |

| MBR | ≈ 7,340 |

| Savings with MAK-HBR™ vs MBR | ≈ ₹4,580 Crore over 10 years |

Over a 10-year horizon, MAK-HBR™ delivers the lowest, most predictable life-cycle cost by eliminating membranes,

minimising chemicals, and reducing power and manpower dependency — while delivering drinking water quality.